Technology of cold rolling GR5 titanium alloy tube

GR5 titanium alloy is one of the most widely used titanium alloys at present. It has high strength and good corrosion resistance. But it is difficult to see GR5 seamless titanium tubes in domestic and foreign markets.

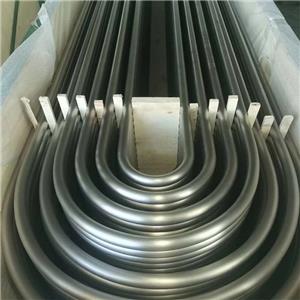

GR5 titanium is mainly made of plate. GR5 titanium tube in the market is mainly made of high-strength thick wall tube by hot extrusion or piercing. The warm rolling process needs to improve the traditional rolling, that is, installing an induction heating device on the pipe rolling machine. This kind of processing equipment has a complex structure, complicated process, and high production cost. The main reason for this situation is the high strength of GR5 titanium alloy and the difficulty of cold rolling. To solve the key technology of GR5 seamless tube cold rolling forming, a series of research has been carried out by school-enterprise cooperation. If the direct cold rolling process is used to produce high-strength titanium alloy tubes, the production cost can be greatly reduced, and the requirements for high-performance applications of titanium alloy can be met at the same time.

The tube with 70% total deformation was produced by two passes and three passes rolling respectively with different amounts of deformation. After 800 ℃ annealings in vacuum for 1 h, the cooling method was furnace cooling to 500 ℃ and air cooling to room temperature. The conclusions are as follows

In the case of small deformation, the wall thickness deviation is small, and the surface roughness gradually decreases. A large amount of deformation and large wall thickness deviation will affect the wall thickness deviation of subsequent passes.

Under the same total deformation, the more rolling passes, the greater the elongation, hardness, and strength of the tube. Good comprehensive performance.

Under the same heat treatment conditions between passes and subsequent rolling process, the microstructure distortion of the tube with large deformation is more serious.

The small deformation has little effect on the anisotropy of the tube. The anisotropy of mechanical properties fluctuates in multi-pass rolling.