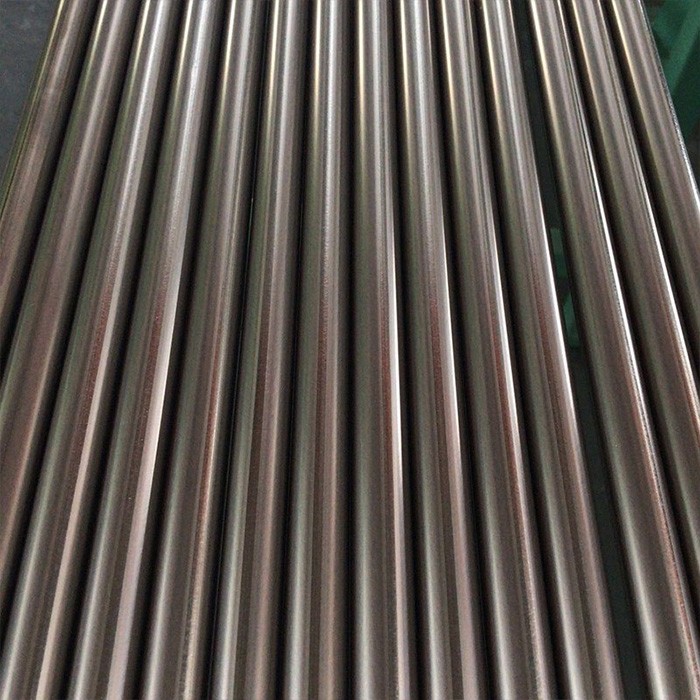

Titanium Welded Tube

- China

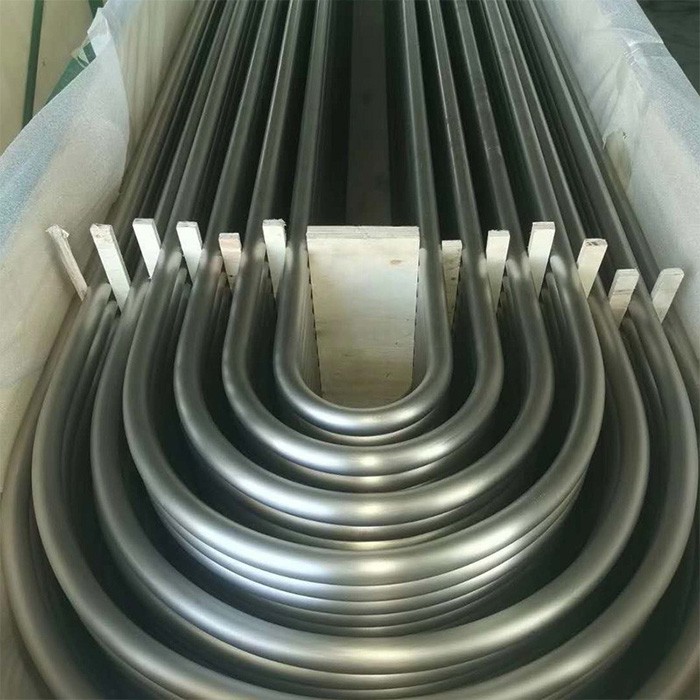

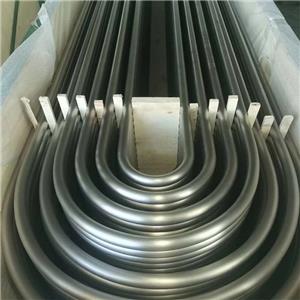

Power Plant Condenser, Sea Water Desalinization, Petroleum, Chemicals, Medical Appliance, Ship Building, Papermaking, Food Processing, Fluid Transportation Piping, Automobile Exhaust Pipe and so on.

1. Standard:ASTM B338, ASTM B862.Executive Standard: ASTM B338, ASTM B862.

2. Material: Gr1, Gr2.

3. Specification: Outside diameter: 6mm-89mm, Wall thickness: 0.35mm-2.0mm, Length: According to your own requirements.

4. Tolerance: As per executive standard requirements, for those tubes which require high precision, we can make according to your own tech requirements.

5. Heat treatment: In-line bright annealing.

6. Application: Power Plant Condenser, Sea Water Desalinization, Petroleum, Chemicals, Medical Appliance, Ship Building, Papermaking, Food Processing, Fluid Transportation Piping, Automobile Exhaust Pipe and so on.

Advantages of Titanium Welded Pipe

1. Taking titanium and titanium alloy tubes for heat exchanger and condenser as an example, the standard ASTM B338 shows that the chemical composition, mechanical properties and process properties of titanium welded pipe and titanium seamless pipe are not different or even the same. With the development of welding and heat treatment technology of titanium welded pipe, single gun or multi gun TIG / paw self fusion welding is widely used for thin-walled titanium welded pipe. After welding, online heat treatment process is adopted. By optimizing welding and annealing process, the microstructure of base metal, weld and heat affected zone is basically similar, and the welding stress is eliminated and the weld microstructure is homogenized. Through comparison, it is found that the weld composition of titanium welded pipe is basically consistent with that of base metal, and the mechanical properties and corrosion resistance of weld are the same as those of base metal.

2. Titanium welded pipe is welded by cold rolled strip coil, with uniform wall thickness, good concentricity, good finish, and is not easy to scale in the pipe. In particular, the production of thin-walled titanium tube by seamless rolling process can not meet the technical requirements. It is difficult to achieve wall thickness less than 1 mm for titanium seamless pipe after rolling or drawing process, while titanium welded pipe can achieve wall thickness of 0.5 mm or less, which saves a lot of materials and costs. At the same time, due to the thin wall thickness of titanium welded pipe, higher heat transfer coefficient and better heat transfer effect can be obtained.

3. The production process of titanium seamless tube is complex. The tube blank of certain specification is rolled or drawn by three high or multi roll rolling mill and drawing machine, and then the seamless tube is produced by reducing diameter and wall. The production efficiency and yield of the process are low. Titanium seamless tube from sponge titanium to tube, through rolling or drawing, material waste is large, production cycle is relatively long.

Titanium welded pipe is produced by automatic continuous production line, using titanium strip with uniform wall thickness through cold bending, welding, on-line heat treatment, sizing and straightening, nondestructive testing and air tightness testing. From sponge titanium to welded pipe, the material utilization rate is usually about 80%. If titanium strip coil is used as raw material, the material utilization rate is more than 95%. Price advantage over seamless pipe.