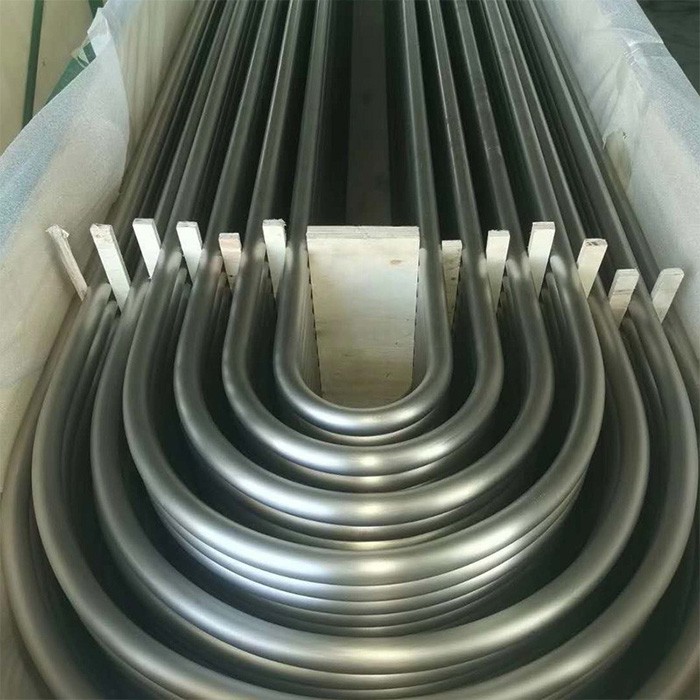

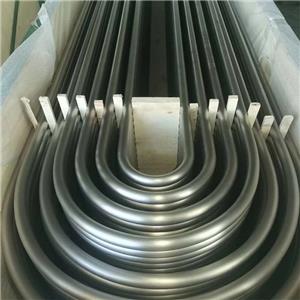

Titanium Tube In Special Grade

- China

ASTM B338/ASME SB338, ASTM B861/ASME SB861 & DIN17861

Standard and Size:

Spec: ASTM B338/ASME SB338, ASTM B861/ASME SB861 & DIN17861

Material: Gr.1 Gr.2 Gr.3 Gr.7 Gr.9 Gr.11 Gr.12 Gr.16 Gr.17

Sizes range: OD 1.5-219mm, WT 0.3-8.0mm, Length≤18000mm

Chemical composition

Element | N | C | H | Fe | O | Pd | Mo | Ni | Ni | V | Residuals |

Grade 5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5-6.75 | 3.5-4.5 | 0.4 max | |||

Grade 7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | 0.12-0.25 | 0.4 max | ||||

Grade 9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | 0.4 max | |||

Grade 12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | 0.2-0.4 | 0.6-0.9 | 0.4 max | |||

Grade 16 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | 0.04-0.08 | 0.4 max |

Titanium Grade 5

Ti Grade 5 has very high strength but relatively low ductility. The main application of this alloy is in aircraft and spacecraft. Offshore use is growing. The alloy is weldable and can be precipitation hardened.

Titanium Grade 7

Ti Grade7, Most corrosion-resistant titanium alloy offering outstanding resistance to general and localized crevice corrosion in a wide range of oxidizing and reducing acid environments including chlorides, with a good balance of moderate strength, reasonable ductility and excellent weldability. Physical and mechanical properties equivalent to Grade 2.

Titanium Grade 9

Ti Grade 9, is sometimes referred to as ‘half 6-4’. It offers 20-50% higher strength than C.P. grades, but is more formable and weldable than Ti-6AL-4V. Grade 9 combines strength, weldability and formability. Alloy has excellent formability plus higher than the strongest unalloyed grade.

Titanium Grade 12

Ti Grade 12 is highly weldable, exhibiting improved strength allowable at increased temperatures, combined with superior crevice corrosion resistance, and excellent resistance under oxidizing to mildly reducing conditions, especially chlorides.

Titanium Grade 16

Ti Grade 16 is corrosion-resistant material offering outstanding resistance to general and localized crevice corrosion ina wide range of oxidizing and reducing acid environments including chlorides. Has a good balance of moderate strength, reasonable ductility and excellent weldabiltiy.