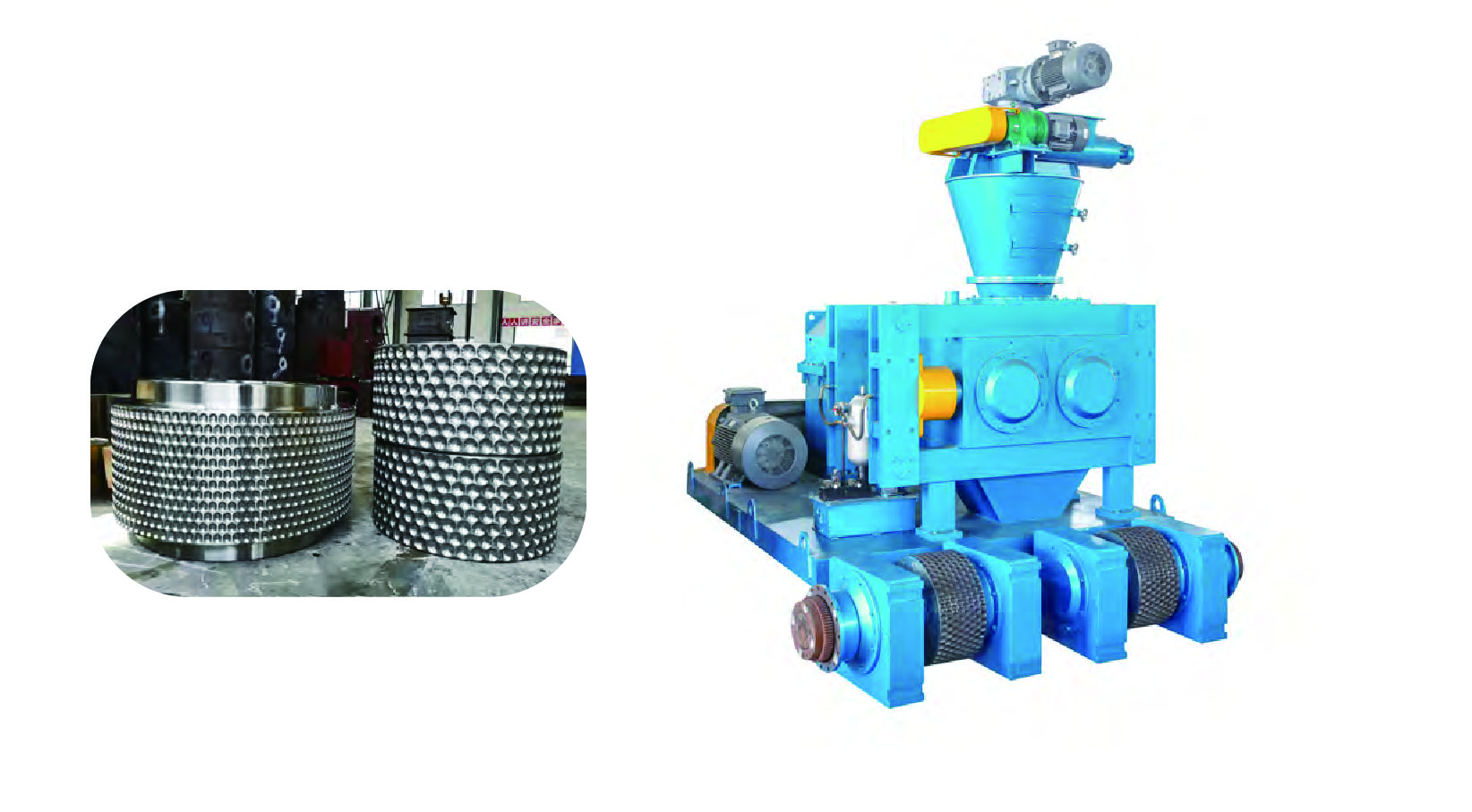

roll rings

spare parts of roll press compactor

We accept customized design for roll rings of roll press compactor

Design Feature

Modular Construction for Customized Flexibility

Briqutting with roller presses follows a simple principle: a fine raw material is fed into the space between two counter-rotating rollers, where it is then compressed and formed into briquettes.

The main functional assemblies provided for this purpose are:

* Press frame

* Pressing rollers with bearings and bearing housings

* Main drive with reduction gear

* Material feeder: Quantitative screw feeding and forced screw feeding

* Hydraulic pressuring system

* Grease lubrication

* Roller housing

The fixed roller is supported directly in the press frame, while the so-called floating roller is also supported in the frame. The movement of the floating roller constitutes the basic principle of a roller press. The rollers are driven by an electric motor in combination with a double-shaft gear box and tooth couplings. This system synchronizes the rollers and allows for the movement of the floating roller.

Controlling the material feed into the roller nip is of paramount importance, whereby a gravity feeder can be used for materials with sufficient flow properties. Other materials may require a screw feeder that forces the material into the nip between the rollers.

The pressing drums are designed as round, or oblate or clam segments, and are fitted with pockets of the desired size and shape. Pressing tools are sturdy and wear-resistant thus ensuring maximum service life and minimum expense. Refurbished pressing tools with a smaller than nominal diameter can also be used.

A roller housing is provided for safety reasons and to minimize dust emission.