Laser Welded Fin Tubes

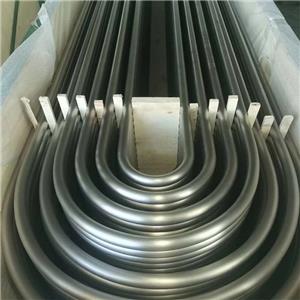

The Laser Welded Finned Tube is a highly efficient and durable heat exchange component widely used in petrochemical plants, power stations, and air-cooling systems. Using advanced laser welding technology, the fins are precisely bonded to the tube surface without filler materials, ensuring excellent thermal contact and mechanical strength. This process eliminates thermal resistance caused by conventional welding, significantly improving heat transfer performance. The Laser Welded Finned Tube offers outstanding corrosion resistance, superior bonding quality, and a longer service life even under extreme temperature and pressure conditions. Compared with traditional high-frequency welded finned tubes, the Laser Welded Finned Tube provides higher energy efficiency, lower maintenance cost, and more stable operation. It is the preferred solution for modern heat transfer equipment that demands precision, performance, and reliability.

1. Introduction to Laser Welded Finned Tube

The Laser Welded Finned Tube is a next-generation product designed for high-efficiency heat exchange in demanding industrial environments. Through advanced laser welding technology, each fin is metallurgically bonded to the tube body, creating a uniform joint with minimal thermal resistance. This precise bonding structure allows the Laser Welded Finned Tube to deliver superior heat transfer performance compared with conventional welded tubes. The design also minimizes material distortion, ensuring dimensional stability and long-term reliability in applications such as petrochemical processing, power generation, refinery air coolers, and boiler systems.

2. Technical Features and Manufacturing Process

The manufacturing process of the Laser Welded Finned Tube uses a fully automated laser welding system that guarantees consistent quality and repeatable accuracy. During production, the laser beam fuses the fin base to the outer wall of the tube, forming a continuous and clean joint without oxidation or micro-cracks. Unlike traditional high-frequency or brazed fin tubes, the Laser Welded Finned Tube requires no filler metals, reducing the risk of galvanic corrosion and contamination.

The Laser Welded Finned Tube can be produced from a wide range of materials including carbon steel, stainless steel, and nickel alloys, depending on customer requirements. The precise control of laser parameters ensures uniform fin spacing and perfect alignment, which are critical for efficient heat transfer and fluid dynamics in heat exchanger design.

3. Performance Advantages of Laser Welded Finned Tube

The Laser Welded Finned Tube demonstrates several distinct advantages that make it superior to conventional welded or extruded finned tubes.

Enhanced Heat Transfer Efficiency: The metallurgical bond between fins and tube wall allows optimal thermal conductivity, minimizing heat loss.

Excellent Corrosion Resistance: The clean weld surface of the Laser Welded Finned Tube improves resistance to oxidation and chemical attack in harsh service environments.

High Mechanical Strength: The joint created by laser welding technology provides strong adhesion, ensuring reliable operation under high thermal stress.

Long Service Life: Reduced thermal fatigue and minimal joint defects extend the operating lifespan of the Laser Welded Finned Tube, reducing downtime and replacement costs.

Customizable Design: The Laser Welded Finned Tube can be tailored in terms of fin height, pitch, and material composition to meet specific heat transfer requirements.

4. Applications of Laser Welded Finned Tube

The Laser Welded Finned Tube is widely used in heat transfer equipment components for various industrial systems. Common applications include air-cooled heat exchangers, waste heat recovery units, economizers, and condenser systems. In refineries and petrochemical plants, the Laser Welded Finned Tube improves the efficiency of thermal processes by ensuring effective heat recovery from exhaust gases and process fluids. In power plants, the Laser Welded Finned Tube contributes to optimized boiler performance and energy conservation. Due to its stable thermal performance and corrosion resistance, the Laser Welded Finned Tube is also ideal for offshore platforms and high-temperature gas coolers.

5. Quality Control and Testing

Every Laser Welded Finned Tube produced undergoes strict quality inspection and testing. Non-destructive testing methods such as ultrasonic and visual inspection ensure that each weld meets the required metallurgical integrity. Surface roughness, fin bonding strength, and dimensional accuracy are checked in every production batch. These quality assurance procedures ensure that the Laser Welded Finned Tube performs reliably in critical operations. The manufacturing process also follows international standards such as ASME and EN specifications, guaranteeing that the Laser Welded Finned Tube meets global industrial requirements.

6. Summary

As an advanced heat transfer equipment component, the Laser Welded Finned Tube represents a significant technological upgrade for energy systems requiring high thermal efficiency and durability. The innovative laser welding technology enables excellent bonding between fins and tube walls, resulting in enhanced heat transfer, corrosion resistance, and structural integrity. With consistent quality and superior performance, the Laser Welded Finned Tube has become an essential element in the design of modern heat exchangers, air-cooling units, and energy-saving projects.