Bulk Solid Heat Exchanger

- JIANGSU VOTTI

- China

1. World leading laser welding pillow plate heat exchange technology

2. Full closed operation with zero emission

3. Saves energy up to 90%

Product Introduction

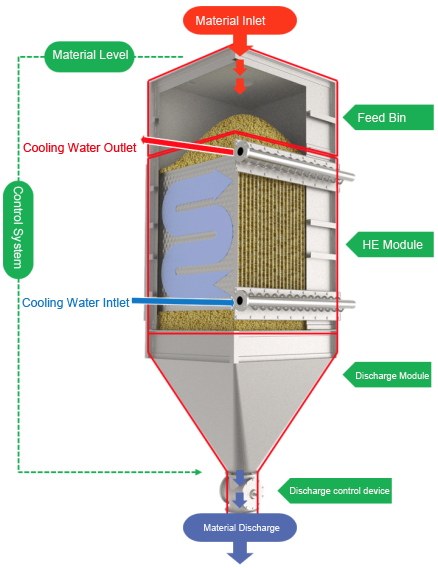

Granular or powder materials enter the equipment feed bin from the top and enter the heat exchange module for heat exchange after being evenly distributed in the feed bin. The material after heat exchange flows from the discharge cone to the discharge device (hinged door, rotary valve, belt, winch or other methods), then sent to the next section.

In the whole heat exchange processing, the flow of materials is completely driven by gravity and forms dense phase transportation. A material level radar is set at the top to monitor the material level signal, and control the discharging speed to adjust the height of materials in the feed bin, so as to keep the whole heat exchange module full of materials, in order to achieve the best heat exchange effect. The vibrator shall be set in the wall of discharging module, and the vibration shall be started regularly according to the actual needs to effectively strengthen the smoothness of discharging.

A certain amount of cold dry gas will be introduced into the SV solid heat exchanger. An appropriate amount of cold dry gas can improve the fluidity of materials and prevent the risks of bridging and condensation inside the equipment.

Product Advantages:

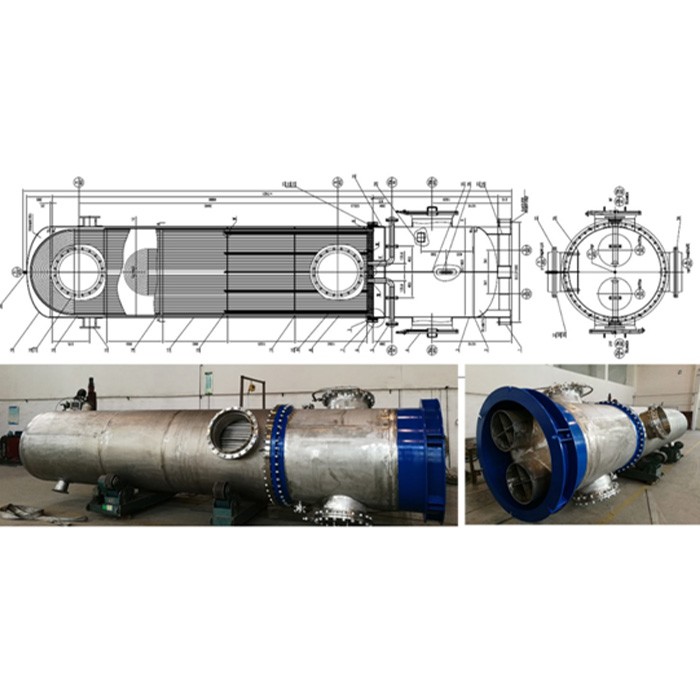

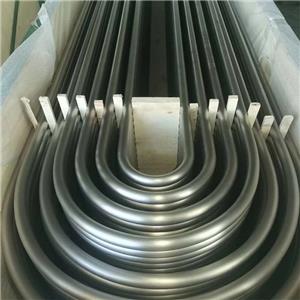

1.World leading laser welding pillow plate heat exchange technology:

Pillow plate is laser welded by two plates all around and in the middle area full of weld flowers. After the forming process, the inner part of the heat exchange plate forms a pillow type cavity. Pillow design creates excellent turbulence and provides self supporting structure. In practical applications, the additional welding path is often added in the pillow heat exchange plate, in order to adjust and control the flow of fluid into and out of the heat exchange plate nozzle position, the fluid velocity and flow rate inside plate, so as to optimize the heat exchange effect.

2. Full closed operation with zero emission:

In the process of using wall type heat exchange technology of SV bulk solid heat exchanger, there will be no direct air contact with bulk solid. So it fundamentally eliminates dust, fine particles and odor emissions, as well as prevent dust explosion effectively.

3. Saves energy up to 90%:

Compared with the traditional heat transfer technology, the energy consumption of SV powder flow heat exchanger is decreased by more than 90%

Application:

SV bulk solid heat exchanger is used in the process of on-line cooling and heating of solid particles,including chemical, fertilizer, polymer, mineral, sand and bulk crop, etc. SV bulk solid heat exchanger uses simple and easy to access medium to exchange heat. For example, cool water from cooling tower or water chilling unit for powder cooling; hot water, steam and heat conducting oil to heat powder. In most applications, energy could be recovered by SV heat exchanger, so enables users to obtain multiple benefits.