What’s the advantage of the new type of vacuum annealing furnace that Votti uses?

As is well-known, vacuum annealing is an important step for titanium seamless tubes. It releases stress and ensures good mechanical property. Especially for Gr9 titanium tube, certain mechanical property of titanium tube is specified clearly in ASME SB338, and we must make sure the actual property stays at right range.

Votti bought the new type of vacuum annealing furnace and put it into use. Following are some of the advantages:

1. High working temperature which is 800℃ can meet the annealing process of various titanium and titanium alloy materials.

2. Large loading size of 800mm and uniform temperature area for effective operation ensures high production efficiency.

3. Large amount of loading. Every furnace of three rooms of loading is maximum 950 kg, every furnace of single room maximum 1500 kg.

4. Production size: three rooms OD12~114× Thk0.5~4×Length13000mm; Single room OD0.5~12-114 x Thk 4 x Length20000mm.

5. Equipment vacuum degree: 2.0×10-1 Pa.

6. Short vacuum time; Vacuum exhaust time: ≦30min.

7. 13 meters three-chamber furnace and 4 areas are convenient for individual temperature control; 20 meter single-chamber furnace and 6 area is convenient for individual temperature control; Temperature control accuracy: ±1℃.

8. Furnace temperature uniformity: ≤±5℃.

9. Argon filled process.

10. Three-chamber furnace is a structure with two cooling chambers connected to the heating chamber, two ends of which are alternately discharging and discharging, one end is fixed and the other end can be extended freely. Both ends of intermittent alternating feeding, high production efficiency.

11. Three - chamber furnace cooling chamber: two sets, double - layer water - cooled structure, used for rapid cooling of materials.

- Titanium Materials

- Titanium Tube and Pipe

- Titanium Sheet and Plate

- Titanium Bar

- Titanium Forging

- Titanium Pipe Fitting

- Titanium Civilian Product

- Metal Alloys & Specialty Materials

- Fin Tube

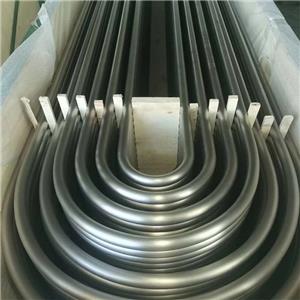

- Stainless Steel Tube

- Copper Tube

- Nickel Alloy Tube

- Beryllium Copper Alloy

- Cladded Plate

- Machined Parts

- Metal Machined Parts

- Metal Machined & Welded Parts

- Mining Machinery & Accessories

- Nylon or PE Machined Parts

- Shaft & Mixer

- Spiral Shaft

- Spool

- Spring & Chain

- Welded Oil Tank

- Screw Feeder & Conveyor

- Bearing Housing

- Expansion Connector