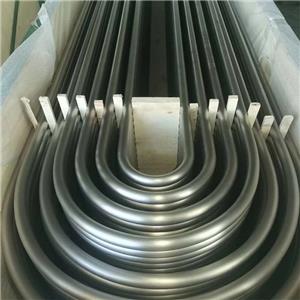

Titanium Laser Welded Fin Tube

At present, there are many kinds of finned tubes in the market, most common product is high frequency welding finned tube. Compared with inlay, brazing and other methods, HFW is more mature in product quality and production automation.

However, due to the fact that the root of the high frequency welded finned tube is difficult to be welded through and the root has wrinkles and other factors, there are still many shortcomings in the heat transfer efficiency and not easy to deposit ash of the high frequency welded finned tube.Laser welded finned tube has been a mature product, which has following good advantages:

1. The thickness of base tube and fin can be 0.8-1.5 mm and 0.3-1 mm respectively, which greatly saves the material cost compared with other processes.

2. High penetration rate can prevent gap corrosion, prolong service life and reduce heat transfer resistance.

3. No material restriction, different materials can be used for processing.

4. Easy for secondary processing, can be directly coiled and bent.

5. The welding heat affected zone and the metallographic change are small, which makes it possible to process the small diameter finned tube.

6. A variety of material combinations are available, titanium / copper, titanium / titanium, carbon steel / carbon steel, stainless steel / stainless steel, stainless steel / copper, etc.

As the largest seamless titanium tube factory in China, Jiangsu Votti not only pays attention to the improvement of product quality, but also carries out the development of product diversity and technological innovation. As the first enterprise engaged in the research and development of titanium laser finned tube in China, we have successfully mastered the production technology experience of titanium laser fin tube, and successfully supplied it to domestic and foreign users, which has been highly recognized by customers.

- Titanium Materials

- Titanium Tube and Pipe

- Titanium Sheet and Plate

- Titanium Bar

- Titanium Forging

- Titanium Pipe Fitting

- Titanium Civilian Product

- Metal Alloys & Specialty Materials

- Fin Tube

- Stainless Steel Tube

- Copper Tube

- Nickel Alloy Tube

- Beryllium Copper Alloy

- Cladded Plate

- Machined Parts

- Metal Machined Parts

- Metal Machined & Welded Parts

- Mining Machinery & Accessories

- Nylon or PE Machined Parts

- Shaft & Mixer

- Spiral Shaft

- Spool

- Spring & Chain

- Welded Oil Tank

- Screw Feeder & Conveyor

- Bearing Housing

- Expansion Connector