Performance advantages of titanium low finned tubes

The heat exchanger made of titanium low finned pipes has the characteristics of resistance to seawater corrosion and acid corrosion. The superior heat transfer capability of titanium low finned tubes, combined with high-density and low fin design, can reduce the size of heat exchangers and improve their performance. Seawater is an inexhaustible source of cooling water for offshore petrochemical facilities. When selecting the material of the heat exchanger, it is necessary to understand the corrosiveness of seawater to it. Under the action of seawater, copper nickel alloy fin tubes or carbon steel fin tubes will gradually corrode, while titanium low finned tubes have unique properties such as high strength, excellent corrosion resistance, and long-lasting resistance to seawater erosion.

Under the same thermal load conditions, titanium low finned tubes possess both the superior physical properties of titanium materials and the high heat transfer capacity of finned tubes. Its length is only half that of regular bare tube. This technology can be applied to equipment modification and manufacturing conditions of new equipment.

At the same investment as ordinary tubes, heat exchangers made of titanium low finned tubes have smaller dimensions, lower maintenance costs, and can improve the working condition of the heat exchanger and extend its service life. Due to its passivity to seawater, titanium material can resist erosion, corrosion, scaling, and rusting. Compared with materials that are prone to corrosion, titanium finned tubes can effectively prevent scaling on the tube side. The surface of titanium metal will form a tough oxide film (mainly TiO2). When it is mechanically damaged, it can form a new oxide film in an oxidizing environment. This tough and smooth film enables the titanium tube to increase the flow rate of seawater on the tube side, while also resisting impact, turbulence, erosion/cavitation, and physical damage, as well as preventing pitting corrosion by chloride ions and crevice corrosion caused by seawater bacteria.

The strength to weight ratio of titanium material is large, which reduces the thickness of the tube wall and greatly saves raw materials. To achieve better heat exchange function, the inner diameter of the finned tube should be smaller to allow for a higher speed and a larger amount of seawater to pass through (as long as a higher pressure drop is allowed in the application). The magnitude of the pressure drop can be limited by the appropriate design of the inner diameter and length of the finned tube.

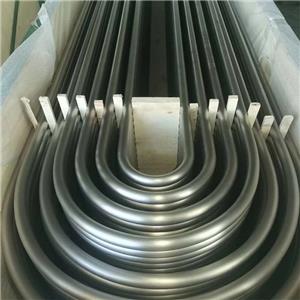

The overall high-density low finned tube has a fin height of 0.5-1.5mm, with a fin density of 19-43 fins per inch. Compared to the bare tube, the surface area of the outer side of the finned tube cooled by seawater increases by three times. In areas where bare tubes waste heat transfer potential on the tube side, a larger surface area can balance heat exchange between the shell side and the tube side.

Increasing the heat transfer area on the shell side can reduce the length of the heat exchange tube by half. Other benefits of having a larger surface area on low finned tubes are:

(1) Reduce the pressure on the shell side of the heat exchanger to half of the bare tube.

(2) Reduce the size of the heat exchanger by 50%.

(3) Can reduce the number of required heat exchangers.

In situations where equipment spacing is very important, smaller heat exchangers can adapt to smaller intervals. Small intervals can reduce the layout size, making inspection and maintenance easier to operate.

XUYI TITAN as the biggest private titanium tube manufacturer in China, which have integral titanium tube production chain from melting raw material, extruding hollow billets and rolling to finished tubes.

That’s mean we have strong titanium fin tube production ability, price advantage and quality control.