Application of titanium and titanium alloy in vacuum salt making equipment

In the vacuum salt making system, the raw material is brine, which contains a large number of corrosive media. Its main equipment, such as brine preheater, heater and evaporation tank, are exposed to high concentration brine for a long time at high temperature and are constantly impacted by salt sand. Under this condition, the equipment should operate normally for a long time, and anti-corrosion is the key problem.

There are many reasons for corrosion, among which the existence of O2, high temperature, Cl - and solid salt scouring are the main factors. The commonly used anti-corrosion methods include deoxidation, pH adjustment, electrochemical protection, coating protection, the use of anti-corrosion materials, etc. The use of anti-corrosion materials is a very effective way of anti-corrosion, and the application of titanium and titanium alloy in vacuum salt making is one of them.

Preheater

The raw materials shall be preheated before entering the heater to save energy. In the past, the preheater often used tubular heat exchanger. The material of the heat exchange tube is made of carbon steel, which is very easy to be blocked and corroded. The heat exchange tube often needs to be replaced and stopped for maintenance, which brings great inconvenience to the production. There are also red copper tube preheaters, the corrosion still exists, the service life is extended to 1 year, but it is still very short, and the cost of red copper tube is high.

Until the emergence of titanium plate heat exchanger. The heat exchange surface of plate heat exchanger is plate. Although its strength is not as strong as that of tubular heat exchanger, it has good heat transfer effect, less materials, light weight, easy maintenance, and its service life can reach 15 years. For example, the pure titanium plate heat exchanger used in Zigong Ziliujing salt plant has been used since 1994. The titanium plate is still as bright as new, has never been replaced, and has obvious economic benefits.

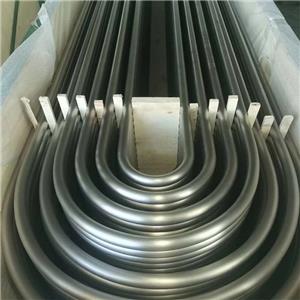

Heater

Since the heat exchange tubes of the heater are closely arranged on the tubesheet, the maintenance and overhaul are quite time-consuming, and all the heating tubes need to be replaced once a year. The temperature of Effect II and effect III is lower, and the heating tube can be used for about 2 years. The minimum temperature of effect IV can only be used for 4 years and needs to be replaced. During overhaul, the shutdown delays production, reduces production, seriously affects production, and the maintenance cost is high (some manufacturers use red copper in the heating chamber, the situation has improved, but the service life of effect I is only 3-5 years). In view of the characteristics of titanium, if titanium is used in heaters, the situation will be greatly improved.